There aren’t many months without at least a couple of guitars coming in with broken necks.

Very often it’s a Gibson guitar which has taken a tumble.

While mahogany is a great wood to work with, it doesn’t cope well with sudden impact and tends to fracture just where the pitched headstock meets the neck.

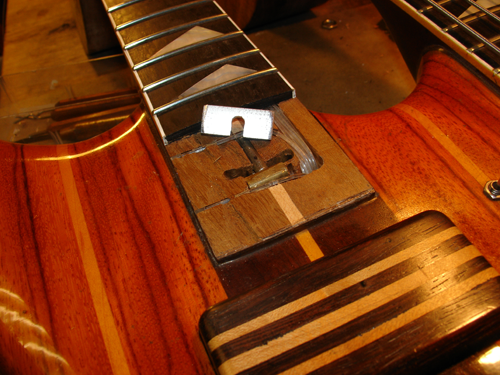

This ES-335 didn’t want to go back together until I made an ebony peg to strengthen the area across the repaired break.

The increased glue-able surface area, created by the addition of the peg, was just what was needed and I’m quite pleased with the result.